The previous column explained the outline of a lathe using a machine configuration schematic view.

Today, as announced in the previous column, spindle will be deeply explained!

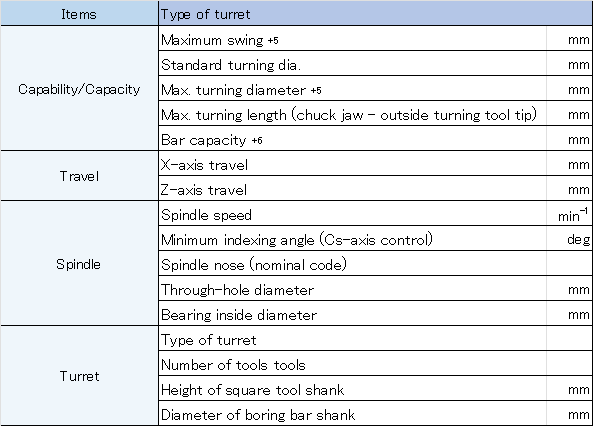

Also, as before, indicators will be explained using the TCN-2100 product catalog.

Click here to look back the previous column.

[For beginners] Self-study column by TAKISAWA staff: What is lathe?

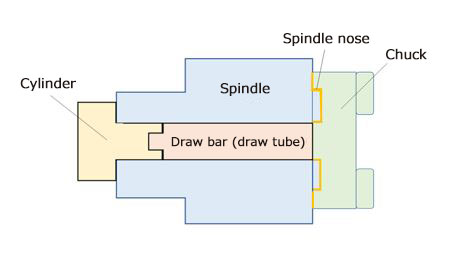

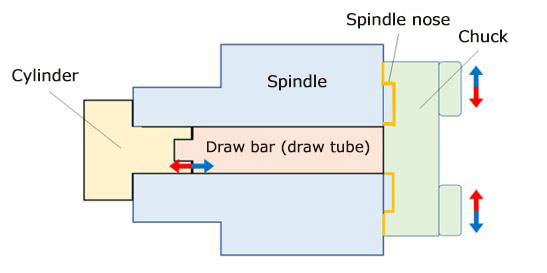

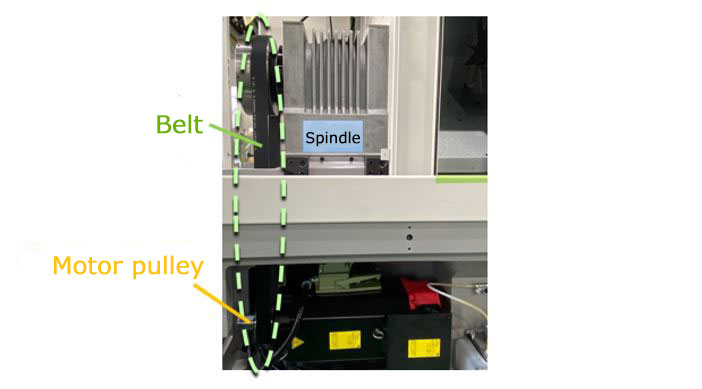

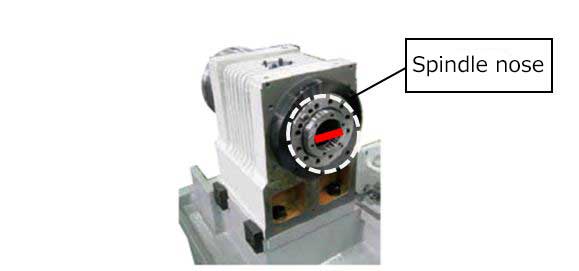

Let’s review the previous column. Do you remember what a spindle is?

Spindle is “a shaft that rotates a workpiece attached to it”.

As it is an important component directly linked to machining accuracy, it must rotate quietly and smoothly as its basic characteristics.