The hot days continue, but are you performing daily inspection properly?

We are working while taking water, and machines also require maintenance.

How do you perform daily inspection?

Machine instruction manuals have quite a few pages. If you have not read them thoroughly, we hope you recognize the importance of daily inspection anew, and actually perform the inspection by referring to this article.

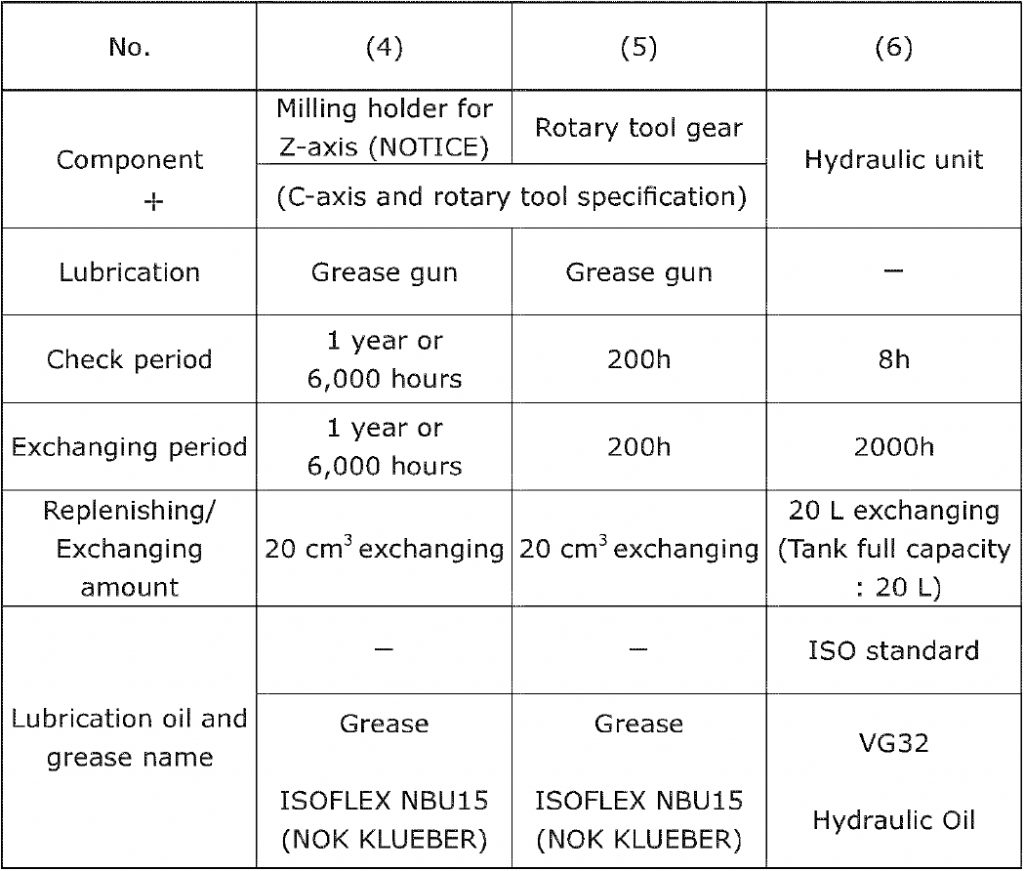

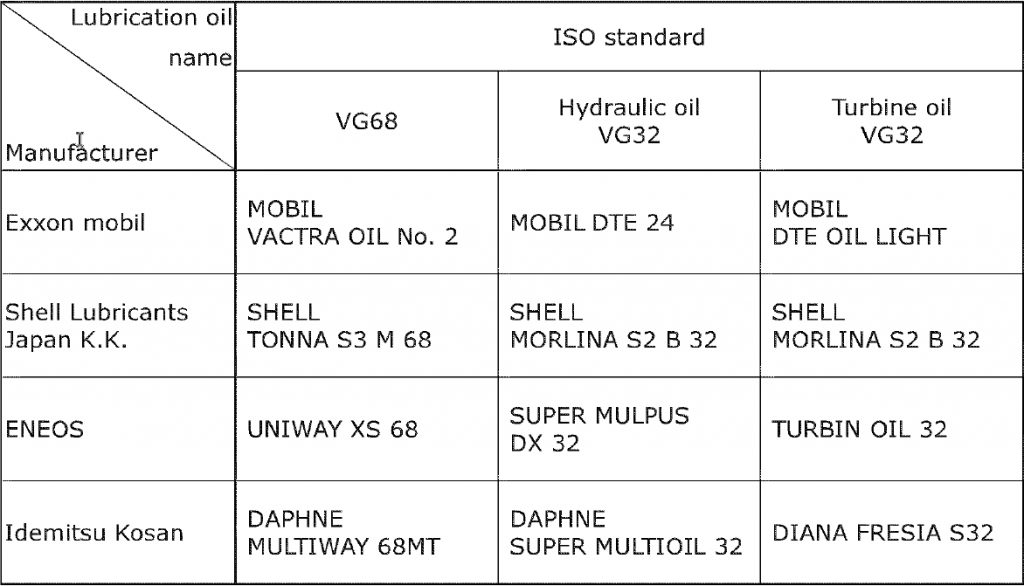

This article explains oil replenishment work, which is performed most frequently.