product

TCN-2600

TCN-2600New

New model of 10" TCN chosen around the world for its high cutting capability and versatility!

- All slideways use highly rigid and highly accurate rectangular slides.

- Continuous rated torque is improved compared to former machines by reviewing the spindle motor and reduction ratio.

- Two types of 8-(Standard) and 12-station milling turret are available.

- Supporting highly rigid hydraulic tailstock (Optional)

Machine Main Specifications

| (Turning) | (Turning&Milling) | ||||

|---|---|---|---|---|---|

| TCN-2600 L3 | TCN-2600 L6 | TCN-2600CM L3 | TCN-2600CM L6 | ||

| Chuck Size | inch | 10 | 10 | 10 | 10 |

| Type of Turret | 8-Station Turret (Direct-Mount Type) |

8-Station Turret (Direct-Mount Type) |

Rotary Tool Type 12-Station Turret | Rotary Tool Type 12-Station Turret |

|

| Max. Turning Diameter | mm | φ410 | φ410 *2 | φ280 | φ280 |

| Max. Turning Length | mm | 250 | 550 | 158 | 458 |

| Bar Capacity *1 | mm | φ74 [OP. φ90] | φ74 [OP. φ90] | φ74 [OP. φ90] | φ74 [OP. φ90] |

| Spindle Speed | min-1 | 3200 [OP. 2500] | 3200 [OP. 2500] | 3200 [OP. 2500] | 3200 [OP. 2500] |

| Rotary Tool Speed | min-1 | - | - | 6000 | 6000 |

| Rapid Traverse Rate | m/min | X : 24 / Z : 30 | X : 24 / Z : 30 | X : 24 / Z : 30 | X : 24 / Z : 30 |

| Spindle Motor (30 min/continuous) Wide Range Motor |

kW | 11/9 | 11/9 | 11/9 | 11/9 |

| Rotary Tool Motor (15 min/continuous) |

kW | - | - | 5.5/3.7 | 5.5/3.7 |

| Machine Height | mm | 1700 | 1700 | 1700 | 1700 |

| Required Floor Space | mm | 1750×1543 | 2095×1543 | 1810×1543 | 2277×1543 |

| Machine Weight | kg | 2700 | 3200 | 2800 | 3300 |

*1) Please note the bar capacity follows types of chucks and cylinders.

*2) Due to the spec. of L6, there might be the limit for maximum turning diameter depending on the work size. Please refer to " The Limit of the Turning Range" of catalog.

TCN-2600G

We respond to the automated request.

Compact Automation is realized!

| Outside Diameter | mm | φ200 |

| Length | mm | 140 |

| Weight | kg | 5 (×2) |

| Number of Pallets | 14 | |

| Loading Capacity(Per Pallet) | kg | 70 |

| Work Stacking Height | mm | 400 |

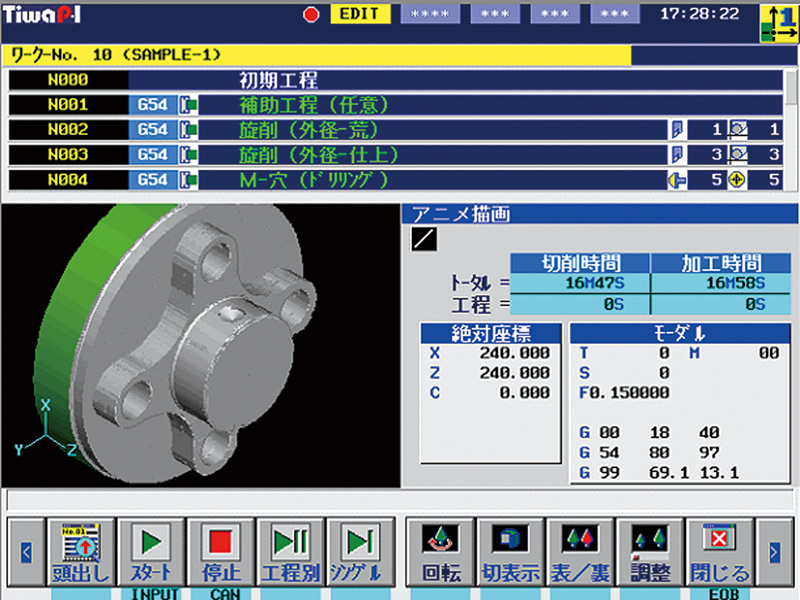

Takisawa Original Software

Supporting Tiwap-1(Optional)

"TiwaP-1" is an interactive programming system fully supporting creation, simulation, and execution of machining programs to reduce operator' labor.

"Input" by the interactive system is easy for the operator to create programs without knowledge of G codes. "Check" of programs can be done by simulating the cutting results with 3D animation and tool path drawing. In "Operation", the machining spindle and the order of process types are automatically recognized to optimally execute spindle control and C-axis zero return.