product

iHMI Software

iHMI Software Human-Machine Interface

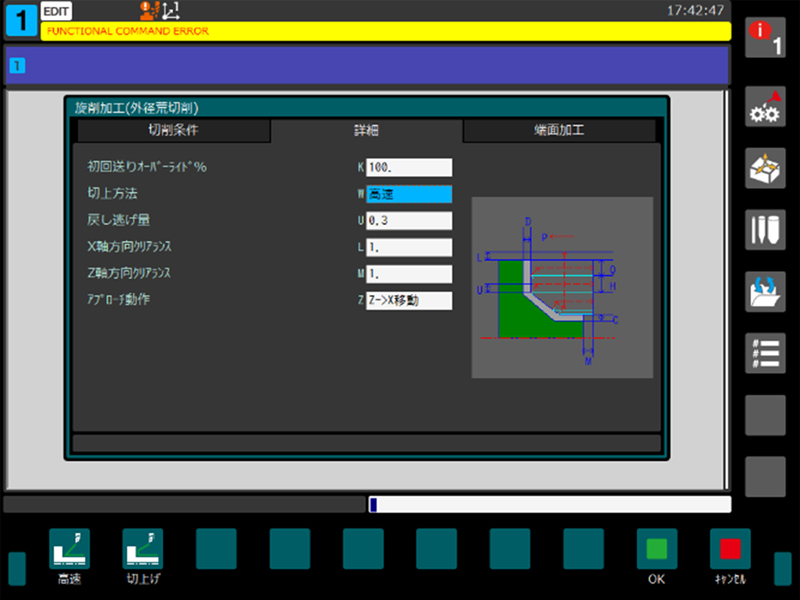

Process Cycle

Process Cycle is standard.

From a program editing screen, you can make a turning cycle and a milling cycle.

TAKISAWA Original Function

Equipped with various original software as standard equipment.

It can switch to various screens instantly from the vertical soft key.

Tailstock Screen

The pressing position, thrust, etc. can be set on the screen.

Steady Rest screen

The steady rest position can be set on the screen.

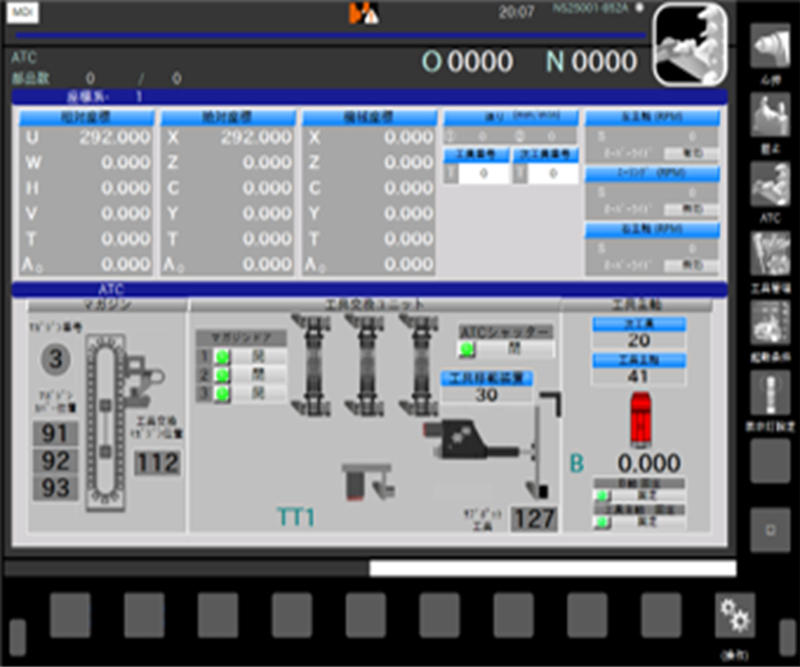

ATC Screen

Display the status of the ATC system, pot number, etc.

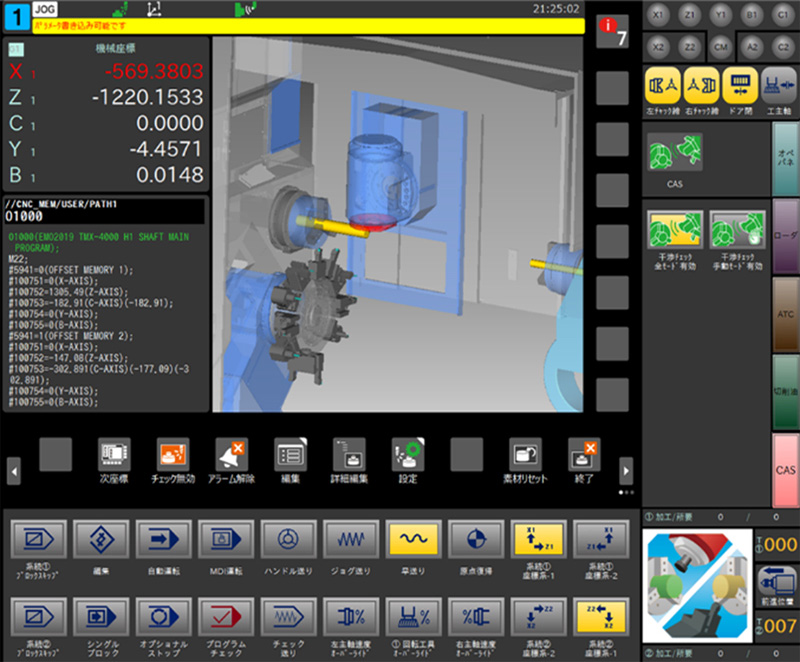

Machine Collision Avoidance (PANEL iH Pro)

The machine collision avoidance function detects a collision beforehand to safely stop the machine by performing a simulation based on the 3D machine model and the preview position of the machine.

You can define the blanks and jigs. You can use standardized shapes and also model files (such as STL and DXF) created in CAD as blanks and jigs.

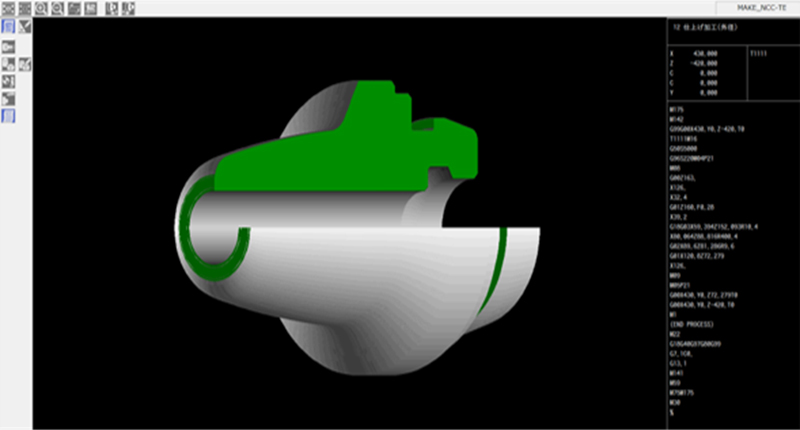

FANUC iCAP T(PANEL iH Pro)

CAD data, in addition to familiar symbolic key input (2D/3D DXF and IGES formats are supported) is available

Supports milling including slant surface in addition to turning. Reduces programming time with automatic process definition.