product

TMX-4000

TMX-4000

Multitasking Machine with Powerful Tool Spindle and Highly Accurate Left/Right Spindle

Extending the range of target workpieces!

Usability is realized by large axis travel of X-axis 605 mm, Y-axis 260 mm, and Z-axis 1500 mm. Thanks to the large travel amount, highly accurate machining of such as milling and end face drilling is possible by one chucking with the C-axis (spindle) fixed.

High-Precision Indexing Paired with Heavy-Duty Cutting Capability

B-Axis uses a direct drive motor for rotation and a diaphragm brake for clamping, achieving high speed and high accuracy (minimum indexing accuracy 0.0001°).

Machine Main Specifications

| TMX-4000ⅡST | TMX-4000ⅡS | TMX-4000Ⅱ | ||

|---|---|---|---|---|

| Right Spindle Stock | ● | ● | - | |

| Tailstock | - | - | ● | |

| Lower Turret (12-Station) | ● | - | - | |

| Chuck Size | inch | 10+10 | 10+10 | 10 |

| Type of Turret | Tool Spindle with ATC | |||

| Max. Turning Diameter | mm | φ500 | ||

| Max. Turning Length *1 | mm | 1500 | ||

| Bar Capacity(Left Spindle) *2 | mm | φ80 | ||

| B-Axis Swivel Range | deg | 230 (±115) | ||

| Left Spindle Speed | min-1 | 4000 | ||

| Right Spindle Speed | min-1 | 4000 | - | |

| Tool Spindle Speed | min-1 | 12000 | ||

| ATC Tool Storage Capacity | 40 [OP. 80. 120] | |||

| Rapid Traverse Rate | m/min | X1 : 40 / Z1 : 40 / Y1 : 40 / A : 30 | ||

| Left Spindle Motor(S2 30 min/continuous) | kW | 26/22 | ||

| Right Spindle Motor(S2 15 min/continuous) | kW | 22/15 | - | |

| Tool Spindle Motor (S3/S6 25%/continuous) | kW | High : 22/15 | ||

| Machine Height | mm | 3160 | ||

| Required Floor Space *3 | mm | T40:6950×4478 | ||

| Machine Weight | kg | 17000 | ||

●: Standard -: None

*1) The maximum machining length differs depending on the chuck type.

*2) Please note the bar capacity follows types of chucks and cylinders

*3) It includes Side-Discharge Chip Conveyor, Operation Panel, and ATC Magazine.

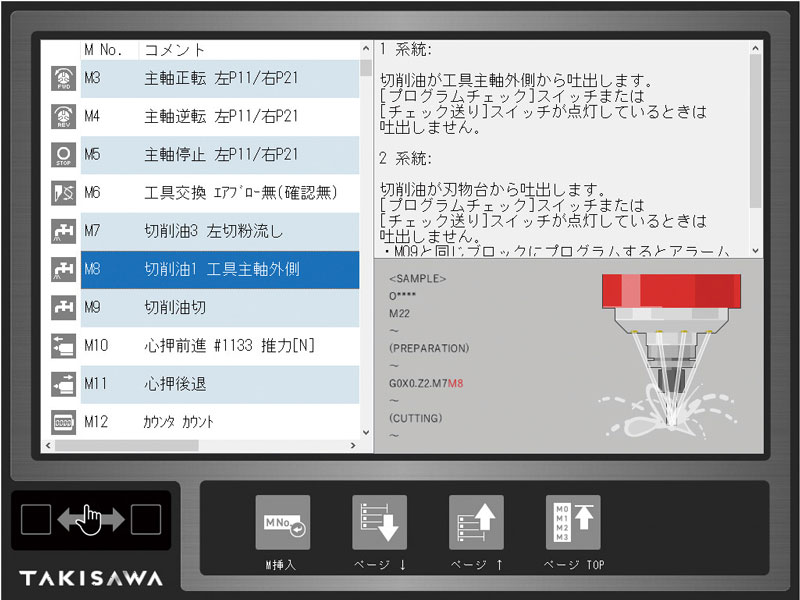

Multi-monitor Operation Panel

The operation panel is now available in two screens, 19" and 10.4".

The 10.4" monitor can be intuitively switched between screens by swiping.

The 10.4" screen not only displays operation buttons, but also displays information you want to know during operation and other convenient functions to strongly support your work.

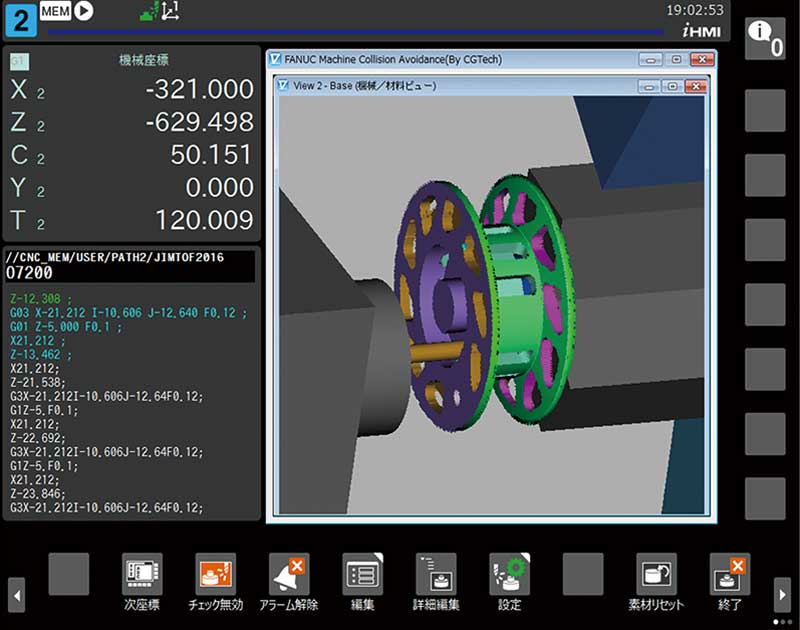

iHMI Human-Machine Interface

Comfortable and easy operation along work flow!!

Consistently supports operation by functions necessary for "Planning", "Machining", and "Improvement" processes on site!

- Supports operation by careless mistake prevention function.

- i HMI Machining Program Creation Support

- Conversational Programming for Lathe(PANEL iH Pro)

- Machine Collision Avoidance (PANEL iH Pro)

Touch Type Operation Panel

Touch Type Operation Panel15 inch (Standard) 19 inch (Option)

Machine Collision Avoidance

Machine Collision AvoidanceTakisawa Original Software

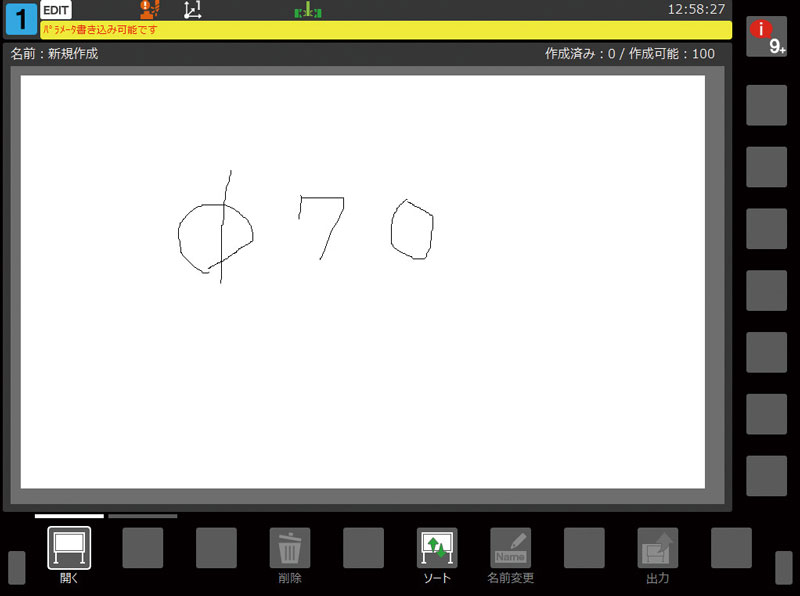

Tiwap-1(Optional)

"TiwaP-1" is an interactive programming system fully supporting creation, simulation, and execution of machining programs to reduce operator' labor.

"Input" by the interactive system is easy for the operator to create programs without knowledge of G codes. "Check" of programs can be done by simulating the cutting results with 3D animation and tool path drawing. In "Operation", the machining spindle and the order of process types are automatically recognized to optimally execute spindle control and C-axis zero return.