product

TT-500GD

TT-500GD

Flexibly Supporting Any Type of Production

High accuracy, automation, and high productivity in minimized space!

TT-500GD supports 5" chuck, which is minimum in parallel twin-spindle CNC lathe TT series. A twin gantry provided as standard is optimum for workpieces with short machining tact time, and the loading time is accelerated to 2.5 seconds. So, the non-cutting time is further reduced.

The high accuracy comb type tool slide is equipped.

Non-cutting time can be reduced compared with the turret type. Five tools can be mounted, sufficient for small parts machining.

Chuck Size : 5"

Loader specification optimum for your production plan is selectable.

Loader Target Workpiece

φ50×50mm、0.5kg×2

Machine Main Specifications

| (Turning) | ||

|---|---|---|

| Chuck Size | inch | 5+5 |

| Type of Turret | Comb Type Tool Slide | |

| Number of Attachable Tools, Tool Slide Width | mm | 5 Tools, 330 |

| Max. Turning Diameter | mm | φ50 |

| Max. Turning Length | mm | 50 |

| Spindle Speed | min-1 | 5000 [OP. 8000] |

| Rapid Traverse Rate | m/min | X : 20 / Z : 24 |

| Spindle Motor(15 min/continuous) | kW | 7.5/3.7 |

| Machine Height | mm | 2145 |

| Required Floor Space | mm | 2560×2512 |

| Machine Weight | kg | 4300 |

| Outside Diameter | mm | φ50 |

| Length | mm | 50 |

| Weight | kg | 0.5 (×2) |

| Number of Pallets | 12 | |

| Loading Capacity(Per Pallet) | kg | 4 |

| Work Stacking Height | mm | 250 |

Feature

Easy process management using dedicated button

Easy measurement management

- Twin gantry optimum for workpieces with short machining tact time is equipped as standard.

- The high power 7.5 kW built-in motor accelerates/decelerates the spindle at a high speed. It takes only 0.8 seconds to reach 5000min-1.

- The comb type turret is the flat type easy for centering. Even for 50 mm workpieces, five tools can be attached.

- Achieving both high rigidity and high accuracy by integrated bed and vibration-dispersing slit structure

- Chip disposal by sufficiently wide 560 mm chip conveyor

- Easy chip change via large maintenance door

The high accuracy comb type tool slide is equipped.

Non-cutting time can be reduced compared with the turret type. Five tools can be mounted, sufficient for small parts machining.

Five tools can be mounted.

The transfer turnover unit is also equipped as standard.

The device allows simultaneous front and back machining.

*Unlike connecting two one-spindle lathes with a reversing device provided between them, even the space efficiency is obvious.

Large Maintenance Door

The right and left machining rooms are provided with the front doors to facilitate tip exchange, etc.

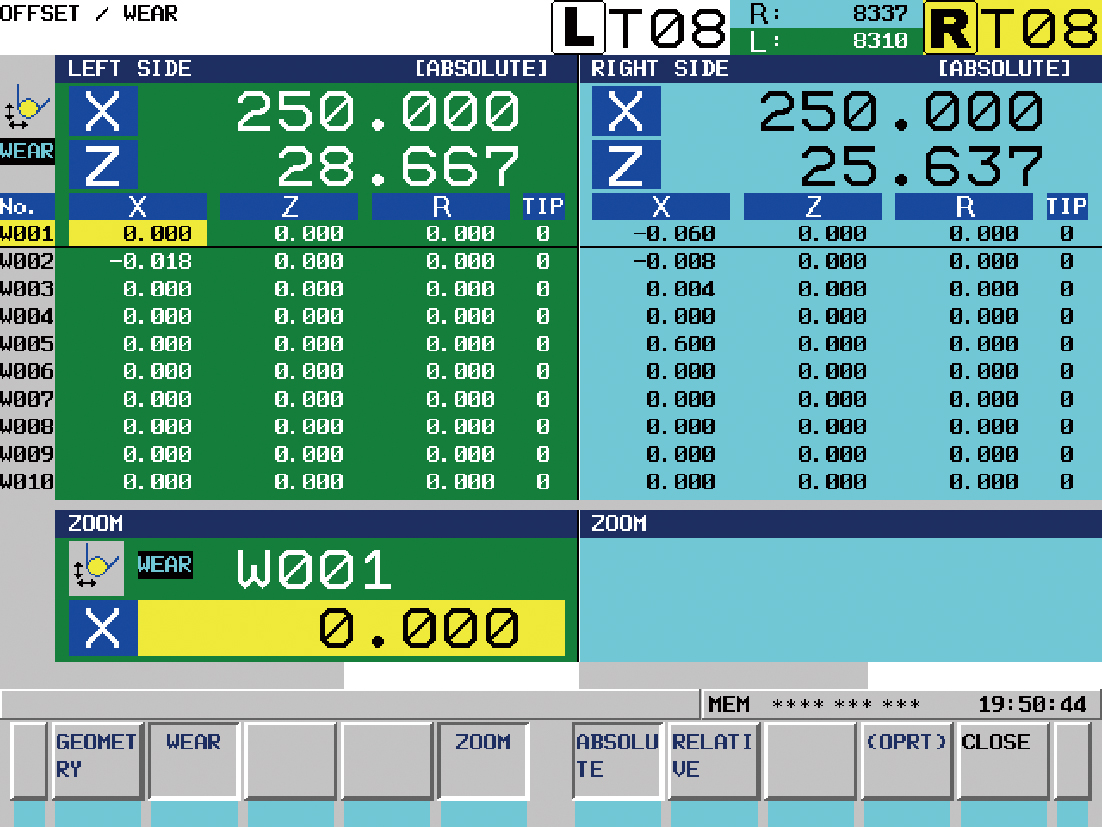

Easy operation by integrating right and left machine information!

Tool Offset Screen (Example)

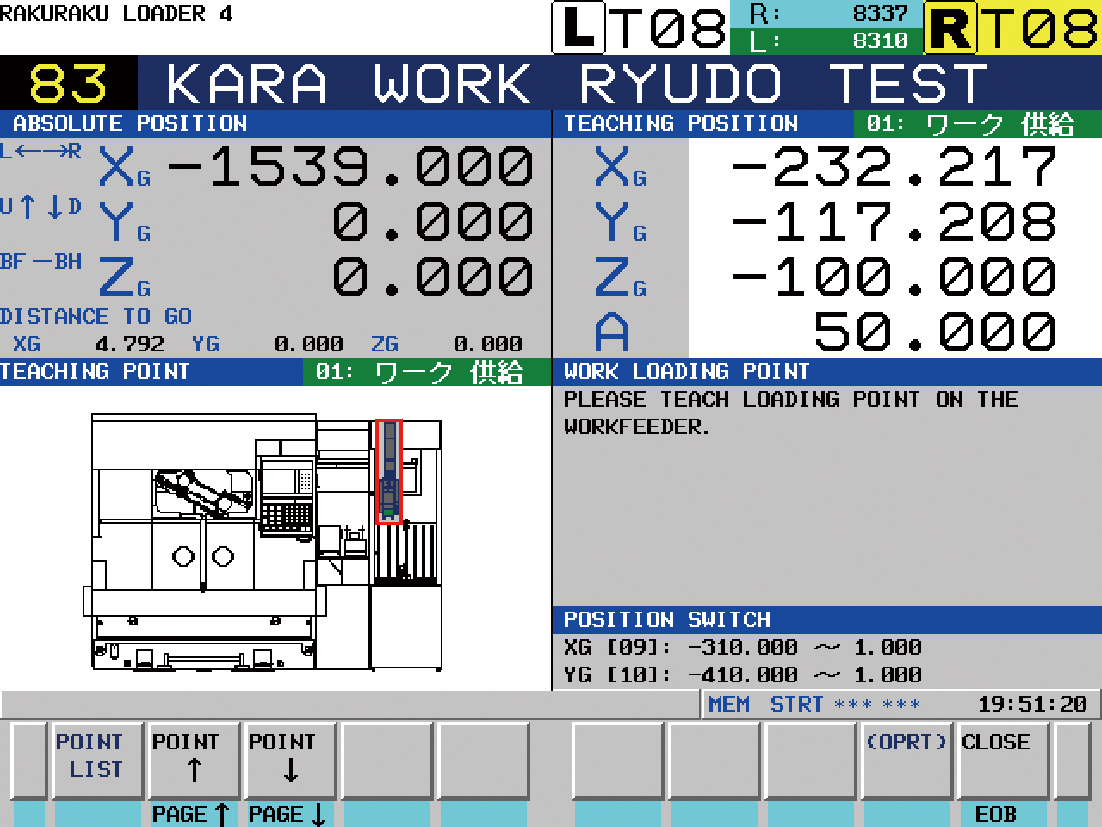

Easy loader teaching by guide diagram!

RAKU-RAKU Loader 4 Screen (Example)